In the end, steel was found. Steel is a compound of iron (ferrite) and a modest quantity of carbon (cementite), normally somewhere in the range of 0.2 and 1.5 percent. Steel was initially made utilizing a cycle called cementation. Bits of iron were put within a Samurai Sword compartment produced using a substance with an extremely high carbon content. The holder was put in a heater and kept at a high temperature for a time span that could go from hours to days. During this time, carbon relocation would happen, and that implies the iron would assimilate a portion of the carbon from the holder. The subsequent combination of iron and carbon was steel.

Practically all swords made today are some sort of steel amalgam. In most present day prepares, there likewise are various different components. You’ll more deeply study the different steel amalgams later. On the whole, we should discuss the devices you want to make a sword. Before a bladesmith (an individual who makes swords, blades and other edged executes) can make a sword, he should have the legitimate climate and instruments. A bladesmith’s shop, called a smithy, is truly similar to a conventional metal forger’s shop. In view of the exhaust and residue made by the smithing system, the smithy should be all around ventilated. Care ought to be given to the position of the produce, blacksmith’s iron and other gear to guarantee that the distance that the bladesmith needs to go with the warmed steel is kept to a base.

The fundamental gear utilized by the bladesmith has changed almost no throughout recent hundreds of years. For most smiths, the greatest change has come after the essential producing is finished, by utilizing power instruments to crush and clean the steel. Secrets to success include: Iron block – The image of the smith, the iron block is effectively the most popular and most conspicuous piece of smithing hardware. A standard iron block has the accompanying parts:

Hammers – The sledge is an augmentation of the bladesmith. He depends on it to make the fundamental state of the sword. Hammers utilized by bladesmiths, and smiths as a general rule, are marginally unique in relation to the common mallet you find in a home improvement shop. The principal distinction is that smithing hammers are delegated, while most standard sledges are not. Delegated implies that the edge of the sledge’s head has been marginally adjusted rather than got down to business. Delegated holds the sledge back from making sharp spaces in the steel as the bladesmith pounds it.

The material utilized in a blade’s development assumes a significant part in its quality and execution. Other than stone, a portion of the world’s most memorable swords were made of bronze. Before long, swordsmiths started making sharp edges with iron, trailed by steel. Be that as it may, one more typical material used to make swords is carbon steel, which contains both steel and carbon. To more deeply study carbon steel blades and why they are famous, continue to peruse.

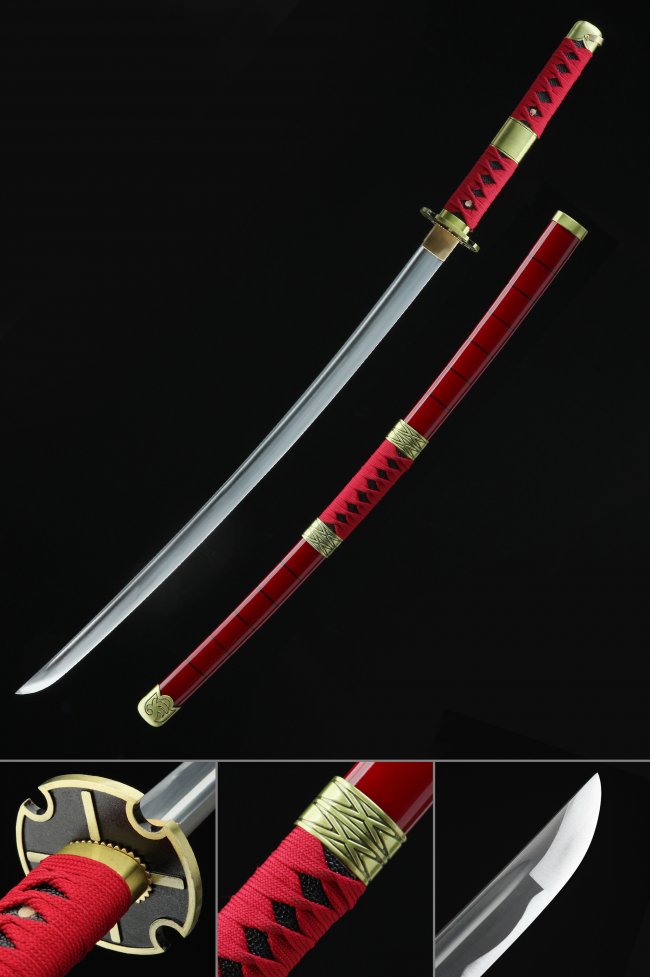

Strong Blade: Most importantly, carbon steel swords highlight an astoundingly solid edge – – considerably more so than treated steel. In medieval Japan, Japan swordsmiths found this attribute of carbon steel; consequently, utilizing it to make the katana. While swords made of different metals would effortlessly break, those made of carbon steel would hold up under fight.